Measuring pore structure of through-holes: The liquid extrusion porosimeter can accurately measure the pore structure of through-holes in porous materials. This is crucial for the production of masks because it ensures the filtration efficiency of the mask.

Analyzing pore size and porosity: This instrument can analyze the pore size and porosity of individual layers in different materials. This helps mask manufacturers choose the most suitable materials and processes to improve the filtration efficiency and comfort of the mask.

Checking ultrasonic sealing of masks: This instrument can detect whether there are any leaks in the ultrasonic sealing of masks. This is essential for ensuring the integrity and effectiveness of the mask, as any leaks can reduce the filtration efficiency and protective ability of the mask.

Generate salt or oil test aerosols in the environment for testing filter efficiency or permeability.

Determine filter efficiency or permeability: The TSI automatic filter tester uses a highly sensitive photometer to determine the filter efficiency or permeability of masks, which can accurately measure the filtering effect of masks.

Ensure the safety of raw materials and mask quality: Using the TSI automatic filter tester can ensure the safety of raw materials and mask quality, as the equipment can test filter efficiency to ensure masks can effectively filter viruses and particles, thereby ensuring masks meet international standards.

Analyze the pore structure of porous materials: The PMI pore size analyzer can detect and analyze the pore structure of porous materials, including narrow pore size, bubble point, pore size distribution, and other micro-pore characteristics, ensuring that the filtration efficiency of mask materials meets international standards.

Measure liquid and gas permeability: The instrument can also measure the liquid and gas permeability of materials, ensuring that the mask can effectively filter particles and viruses.

Measure the external surface area of the pore: The instrument can also measure the external surface area of the pore, which is important for selecting the most suitable materials and processes to improve the filtration efficiency and comfort of the mask.

Wide application range: The instrument is suitable for the micro-pore characterization analysis of various materials, such as technology films, MB non-woven fabrics, nanofibers (electrospun fibers), hollow fibers, PTFE membranes, ensuring the quality and safety of masks.

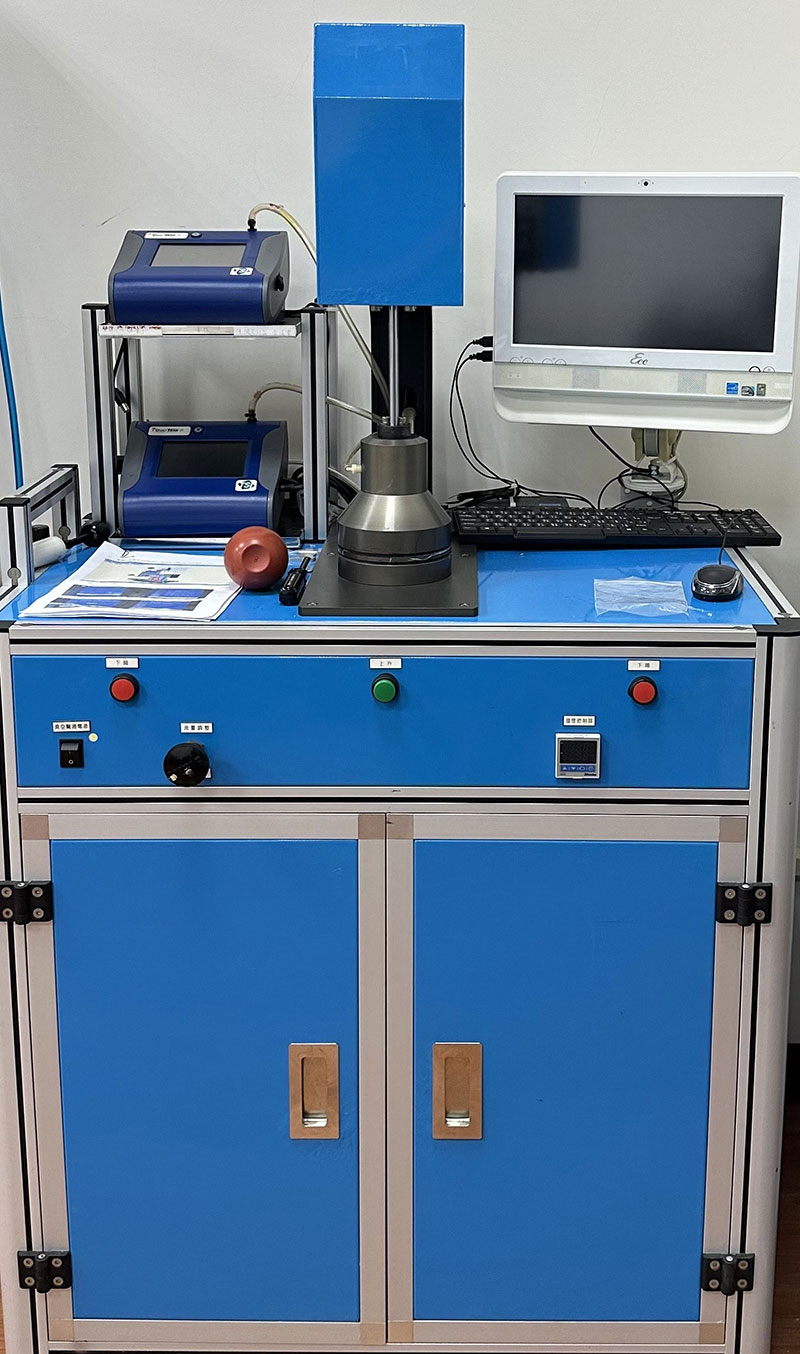

Testing earloop tensile strength: The tensile testing machine can test the tensile strength of the earloops of the mask, ensuring that the mask can fit tightly on the user's face, is not easily detached, and thereby improving the effectiveness and safety of the mask.

Testing the ultrasonic bonding strength of multi-layer materials: The tensile testing machine can also test the strength of the multi-layer materials of the mask after ultrasonic bonding, ensuring that the materials and manufacturing processes of the mask comply with international standards and improve the durability and protective effect of the mask.

Reliable testing tool: The tensile testing machine is a reliable testing tool that can ensure that the quality of the mask meets international standards and further improve the safety and reliability of the mask.

Wide range of applications: The tensile testing machine is not only suitable for mask production and manufacturing, but also for testing a wide range of other products, widely used in various industries to ensure the quality and safety of products.

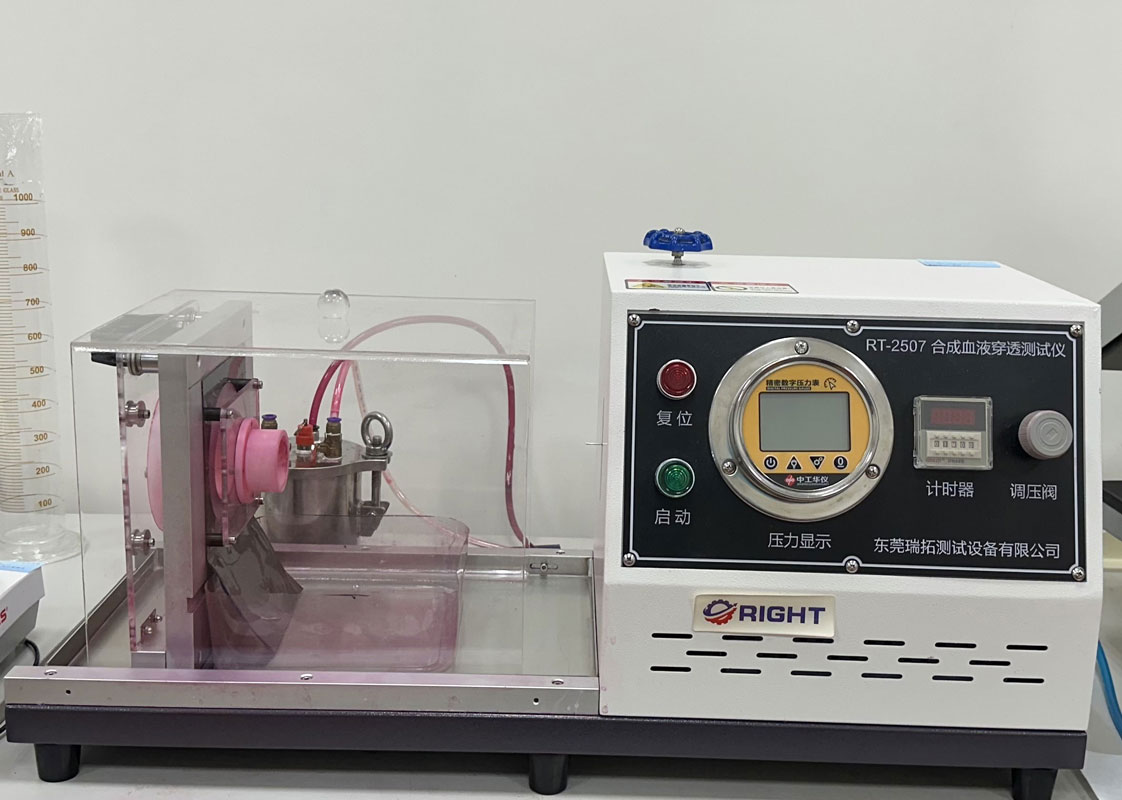

Testing mask filtration efficiency: The blood spray test machine can simulate blood spray scenarios and test the filtration efficiency of masks. This is crucial for testing the protective capabilities of masks, ensuring they can filter out liquid particles such as blood to prevent the spread of viruses and bacteria.

Testing mask protective effectiveness: The blood spray test machine can test the protective effectiveness of masks, ensuring they meet relevant international standards. This helps to guarantee the protective performance of masks and protect the health and safety of users.

Enhancing mask safety: The blood spray test machine can simulate realistic usage scenarios to ensure masks can effectively filter out liquid particles such as blood and prevent the spread of viruses and bacteria, thereby enhancing the safety of masks.

Complying with relevant international standards: The test results of the blood spray test machine comply with relevant international standards such as ASTM F1862/F1862M-17 and EN 14683. This helps mask manufacturers to ensure the quality of their products meets standards, enhancing their credibility and competitiveness in the market.

Testing the breathability of masks: The respiratory impedance tester can measure the breathing resistance of masks, ensuring that the breathability of masks meets relevant international standards. This is crucial for the comfort and respiratory efficiency of mask wearers, ensuring their breathing comfort and efficiency.

Testing the filtration efficiency of masks: The respiratory impedance tester can test the filtration efficiency of masks, ensuring that they can filter out airborne particles such as bacteria and viruses, protecting the health and safety of users.

Improving the quality of masks: The respiratory impedance tester can test the breathing resistance and filtration efficiency of masks, helping mask manufacturers ensure that their products meet standards and improve the credibility and competitiveness of their products.

Complying with relevant international standards: The test results of the respiratory impedance tester comply with relevant international standards, such as EN 149, helping mask manufacturers ensure that their products meet standards, improve the competitiveness and credibility of their products.